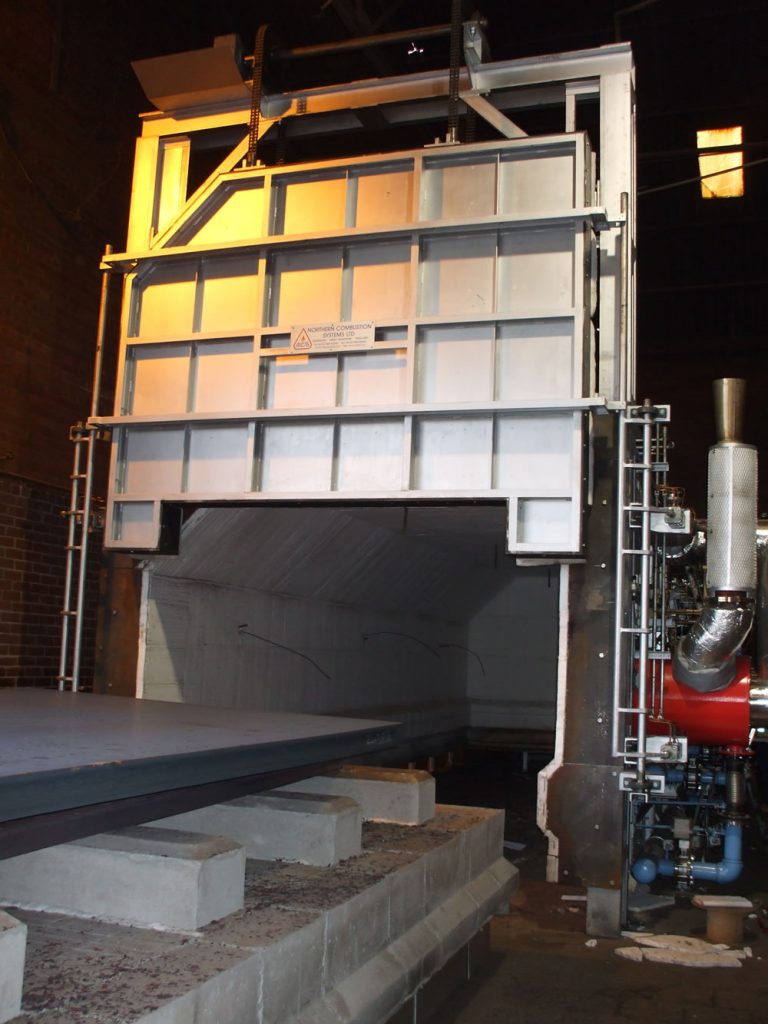

50T Heat treatment Furnace

Working with Goodwin Steel Castings to supply a new 50 tonne heat treatment facility within the Stoke-On-Trent Jubilee Building, Northern Combustion Systems turnkey supply was to incorporate a new 50 tonne heat treatment furnace for the heat treatment of large complex alloy castings. The facility included a charging machine and 500,000 litre water quench tank designed and installed by Goodwin Steel Castings.

The furnace was designed for a load capacity of 50 tonnes plus an 8 tonnes hearth tray, heated in a working survey volume of 5.0m³.

The temperature range of the furnace 200°C to 1250°C was achieved with a temperature uniformity of ±5°C in the range 400°C to 749°C and ±10°C in the range 750°C to 1250°C meeting the requirements of AMS 2750. Minimum heating rate at 10°C per hour and a maximum heating rate at 200°C.

The furnace is fired in 8 zones using four high velocity low NOX hot air burners mounted in the side wall at high level and four in the opposite side wall at low level, suppling a 3.5MW burner rating. Exhaust gas is extracted using eight flue gas recuperators, four each side mounted at low level. This proven firing pattern sets up a high velocity flow of combustion products which circulate the furnace load, resulting in a high degree of temperature uniformity throughout the combustion chamber. The wate gas recuperators provided an overall fuel saving of 36% compared to the existing cold air burner system operating under the same conditions at 1250°C.

The furnace control methodology incorporates, Fixed high air with modulated fuel, Excess Air and Stoichiometric. The system designed to meet with current European safety standards EN746-2 2010.

The furnace design included a 10 Tonne door operated in the vertical plane, counterbalanced driven by a motorised gearbox. A pneumatic door clamping and guide system included to allow quick access of the charging machine to withdraw the heat-treated load for rapid water quenching achieving the crucial grain structure of the maximum 50 tonne load.