Control Panels and Electrical systems

Northern Combustion Systems Limited offer a full in-house electrical team, this includes system designers, PLC programmers, panels builders and installers.

All our Control Panels and systems are designed bespoke to the individual project requirements. Our manufacturing facility utilises the latest technology for both the design and the manufacturing processes, as well as having the backing and support of leading brands such as Siemens, Phoenix Contact & Eurotherm for our components.

Our flexible approach to the manufacture of each Control Panel means we can tailor our designs to meet with the most stringent specification requirements. Our processes and experienced control panel builders ensure we are equipped to deliver to the highest standards for the project’s requirements.

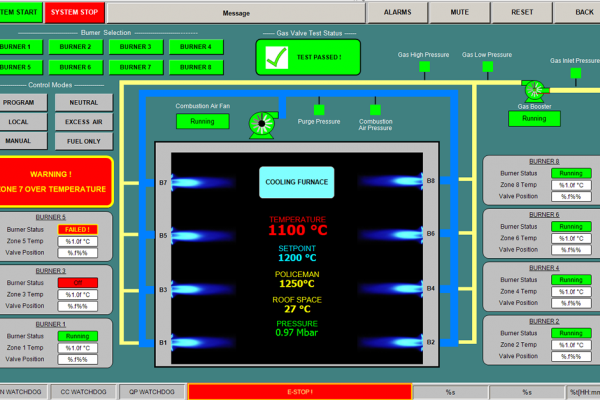

We have undertaken many automation Projects and have designed and built numerous control systems incorporating PLC’s, Operator Interfaces (HMI’s) and supervisory control and data acquisition (SCADA) systems. We also have considerable experience in data recording, data management & process control instrumentation.

When designing control systems, safety is of utmost importance to us. All our control systems are designed using the latest technology on the market to meet current machinery safety regulations and the required safety integrity level (SIL) the project requires. By incorporating safety PLC’s, safety controllers and mechanical/electrical interlocking systems, all with fail safe characteristics, we provide a system that meets our client’s requirements to conform to the ‘Provision and Use of Work Equipment Regulations’ (PUWER)

As well as manufacturing control systems for our own products, our designers and panel builders can design and build control panels for the integration of third-party equipment and associated plant, as well as upgrading existing equipment. This could be to your own design and specifications, or we can give guidance to optimise your options for your project, whether it maybe a small simple system, or a more complex larger system. Whatever the scale of the system, we always keep the complex technical aspect in the background and design a front-end operating system that is easy to use and operator friendly.

Remote support and monitoring are also a service we provide. Our clients benefit from viewing assets or systems and controlling them anywhere there is an internet connection. Remote monitoring can reduce downtime, increase efficiency, and most importantly increase margins and profits of a system whilst also decreasing maintenance costs. Modifications to the software or system can be made remotely, saving time for upgrades and engineers on site. Data can be analysed and used for decision making, giving you full control of not only your electrical systems, but also your business.